3M™ Accuspray™ ONE Replacement Spray Gun – (16579)

3M™ Accuspray™ ONE Replacement Spray Gun – (16579)

$326.00

The 3M™ Accuspray™ ONE Spray Gun delivers fundamental improvements in the application of auto paint and other fluids. A lightweight, 1-piece composite spray gun body contains no gaskets or seals, eliminating the need for maintenance kits. The gun accepts a range of Accuspray™ replaceable atomizing heads for a system affording the performance of a new gun, on demand and at a fraction of the cost.

Easy Cleanup. No Maintenance Kits. A Tremendous Range of Uses.

We asked: “If you could have the perfect spray gun, what would it be like?” The result was our 3M™ Accuspray™ ONE Spray Gun. It’s the only HVLP spray gun that allows for professional-grade application of paint, primer and other fluids with virtually no cleaning and no maintenance kits. This spray gun features a lightweight, composite body that is molded in one piece, eliminating the complexity, wear and cleaning of small parts and pieces like gaskets, seals and O-rings. Convenient, easily-operated controls for fan diameter, fluid and air pressure allow for quick adjustment across jobs from spot repairs to full panel coverage. In fact, this spray gun can handle jobs requiring up to 12” vertical or horizontal spray patterns with very little overspray – one gun for a complete range of applications.

A Spray System That Pays Off

Our Accuspray™ ONE Spray Gun is a central part of our 3M™ Accuspray™ System for automotive collision repair. It effortlessly accepts replaceable atomizing heads – transparent nozzles that can be reused 5-10 times and then simply removed and replaced. Replaceable atomizing heads are clear so it’s easy to see when the head is clean, and the spray guns perform like new every time the atomizing head is replaced – the equivalent of a new spray gun, at a fraction of the cost. The benefits include reduced primer consumption, lower application time and less time for cleanup, plus a better finish which results in less sanding time. The end result: cleaner, more productive, more profitable collision repair operations.

Accuspray™ and Our PPS™ System

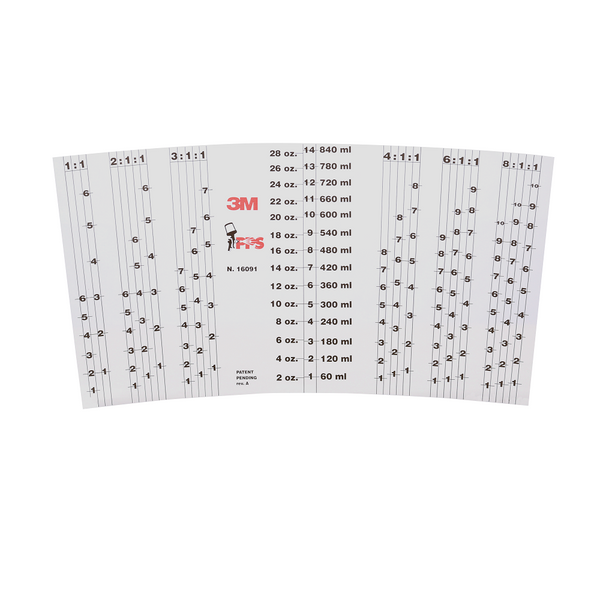

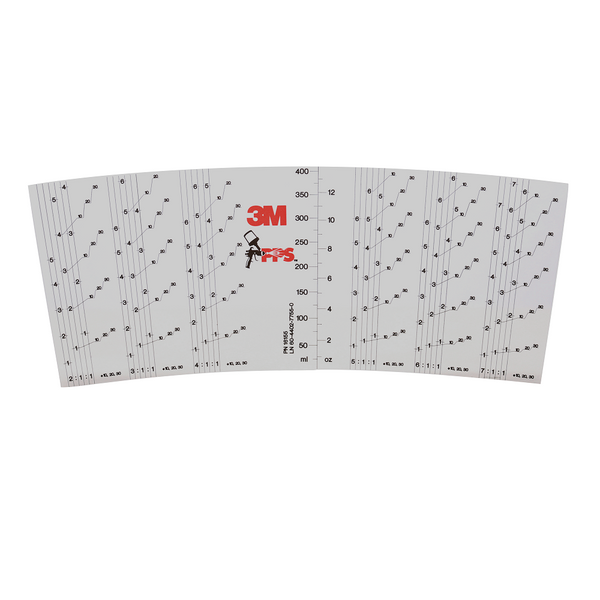

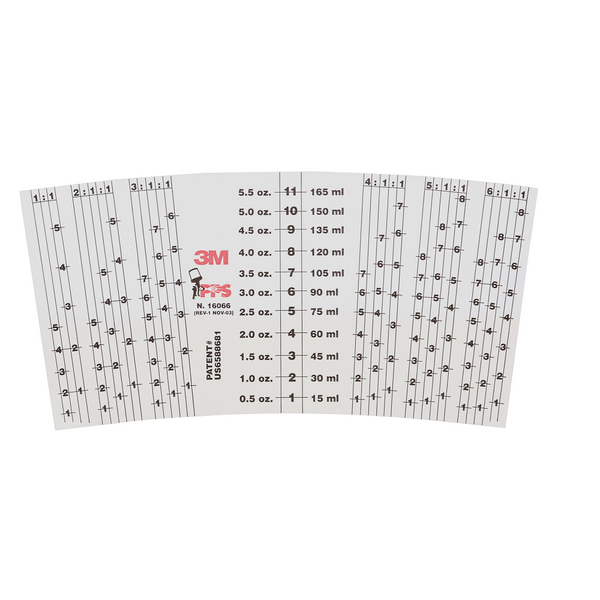

The 3M™ Paint Preparation System is an all-in-one closed system for mixing/measuring, filtering, temporary storage and for spraying in any direction, including upside down, for consistent coverage and improved material usage. This system eliminates the inefficient process of mixing paint and other materials separately and transferring them through filters and other equipment where product gets left behind, unused. Instead, paint and other materials are mixed and sprayed out of the same cup with a PPS™ liner, lid and built-in filter. You simply place a disposable liner within a re-usable paint cup. Then mix the paint in the PPS™ liner, snap the disposable lid (with built-in filter) in place and attach the locking collar to complete the PPS™ System. With just a snap and quick quarter-turn, the assembly easily to the spray gun body. Once you’re finished spraying, simply remove the liner from the cup and discard it. It’s that simple.

There’s no need to spend on the extra mixing cups, filters and strainers. And each PPS™ cup doubles as a temporary container for leftover material – just snap in the included sealing plug to help protect mixed paints, primers and sealants, and save even further on material costs. All of this adds up to a very clear cost savings across your operation. This system lets painters mix less paint, drastically reduce their solvent use, and spend less time cleaning spray guns and cups. All told, the PPS™ system can improve operator efficiency by as much as 15%, and can save up to 70% on solvent usage alone.

The Science of Better Spray Systems from 3M

We put decades of scientific and real-life study into our 3M™ Accuspray™ ONE Spray Gun to help make spray application easier and save collision repair and other professionals time and money at every step. Every feature – from the lightweight composite spray gun body that eliminates maintenance kits to its easy-to-operate controls and varied spray patterns – is another example of what 3M does best: Science. Applied to Life.™

ONE System for Every Spraying Need

The 3M™ Accuspray™ ONE Spray Gun System with PPS™ Series 2.0 is the combination of convenience, versatility and efficiency. This system features the Accuspray™ ONE Spray Gun - a lightweight, composite spray gun body designed to eliminate the complexity of a traditional spray gun. This gun body has been engineered for enhanced durability in automotive and industrial environments. The spray gun uses a series of replaceable, see-through atomizing heads which can be reused 5-10 times and then simply removed and replaced. This affords the performance of a brand new spray gun, on demand and at a fraction of the price.

Replaceable Atomizing Heads for the 3M™ Accuspray™ ONE Spray Gun System with PPS™ Series 2.0

Our 3M™ Accuspray™ Atomizing Heads for PPS™ Series 2.0 deliver the ideal atomization to a wide range of fluids and coatings applied with Accuspray™ ONE Spray Guns. Atomizing heads are available in five sizes: 2.0 mm (red), 1.8 mm (clear), 1.4 mm (orange), 1.3 mm (green) and 1.2 mm (blue). For sealers, basecoats and topcoats, we recommend 1.3 mm or 1.4 mm atomizing heads. Choose the 1.8 mm size for higher-viscosity materials such as primer, and the 2.0 mm size for heavy-duty applications using fluids like gel coats, adhesives, undercoats or industrial coatings. Always refer to your paint company’s recommendations. Fast, easy controls for fan diameter, fluid and air pressure on the Accuspray™ ONE gun allow for quick adjustment across jobs from spot repairs to full panel coverage requiring up to 12” vertical or horizontal spray patterns.

Along with the distinctive color, the fluid tip size is presented clearly on each atomizing head for fast, accurate selection. Atomizing heads are see-through to make it easy for technicians to determine that the head is properly cleaned.

All atomizing heads work with our PPS™ Series 2.0 Spray Cup System – a system of reusable paint cups and disposable lids and liners, so you can be done with cleaning paint cups forever. ONE gun – ONE system for a complete range of applications.

Description

Specifications:

- The 3m™ Accuspray™ ONE Spray gun is for use with compressed air systems only

- Air Inlet - 1/4” NPS (m)

- Maximum air inlet pressure is 24 psi (Maximum inlet pressure will yield approximately 10 psi (0.69 bar) at the air cap)

- Required atomizing air volume is 13 cfm

- Weight – 11.2 oz

- 5 to 8 spray outs before the head needs replacement

- For best atomization results use 13 cfm @ 20 psi

- Part Number 16579, 3M Stock # 7100096183 (Previous 3M Stock # 60455080964), UPC 00051131165793

3M™ Accuspray™ Gravity Spray Gun Kit Includes:

- (1) - 3M™ Accuspray™ Spray Gun Body

- (1) - Air Flow Control Valve & Gauge

- (10) - Color Identification Clips (2 each of 5 colors)

- (1) - Quick start guide & owner’s manual

Atomizing heads and PPS liners and lids sold separately.

Information:

3M™ Accuspray™ ONE Spray Gun System with PPS™ Series 2.0 Spray Cup System - Owner's Manual

Please note that the spray gun does not require a repair kit. For more detailed information on the spray gun such as parts, setup & maintenance, please review the Owner’s Manual.

Note:

3MTM HG and HGP Care and Cleaning Procedures

Do not backpressure the gun.

There are two Teflon O-rings or seals in the atomizing head. When you slide the atomizing head onto the needle the seals are pushed out towards the front of the gun. This seals the needle passage so the air and fluid going through the gun does not blow back into the gun body. If you back pressure the gun it will flip the Teflon seals so they point back into the gun. When you add fluid and pressure it sneaks past the seals and comes out in front of the handle.

The solution is to clean the gun properly.

While the atomizing head is on the gun, fill it half way with whatever cleaner is required for your coating. Cover and shake it a bit to loosen any residue. Pull the trigger and drain. Fill the atomizing head two more times with cleaner and drain through the tip by pulling the trigger. Pull the atomizing head straight off the gun. Do not twist as you're pulling. Fill the needle port on the back side of the atomizing head with cleaner and drain. Inspect to make sure there is no residue left in the atomizing head and repeat if needed.

Related Products

Product Inquiry

Have a question about this product?

Fill the form below and we will respond to you as soon as possible.

Specifications:

- The 3m™ Accuspray™ ONE Spray gun is for use with compressed air systems only

- Air Inlet - 1/4” NPS (m)

- Maximum air inlet pressure is 24 psi (Maximum inlet pressure will yield approximately 10 psi (0.69 bar) at the air cap)

- Required atomizing air volume is 13 cfm

- Weight – 11.2 oz

- 5 to 8 spray outs before the head needs replacement

- For best atomization results use 13 cfm @ 20 psi

- Part Number 16579, 3M Stock # 7100096183 (Previous 3M Stock # 60455080964), UPC 00051131165793

3M™ Accuspray™ Gravity Spray Gun Kit Includes:

- (1) - 3M™ Accuspray™ Spray Gun Body

- (1) - Air Flow Control Valve & Gauge

- (10) - Color Identification Clips (2 each of 5 colors)

- (1) - Quick start guide & owner’s manual

Atomizing heads and PPS liners and lids sold separately.

Information:

3M™ Accuspray™ ONE Spray Gun System with PPS™ Series 2.0 Spray Cup System - Owner's Manual

Please note that the spray gun does not require a repair kit. For more detailed information on the spray gun such as parts, setup & maintenance, please review the Owner’s Manual.

Note:

3MTM HG and HGP Care and Cleaning Procedures

Do not backpressure the gun.

There are two Teflon O-rings or seals in the atomizing head. When you slide the atomizing head onto the needle the seals are pushed out towards the front of the gun. This seals the needle passage so the air and fluid going through the gun does not blow back into the gun body. If you back pressure the gun it will flip the Teflon seals so they point back into the gun. When you add fluid and pressure it sneaks past the seals and comes out in front of the handle.

The solution is to clean the gun properly.

While the atomizing head is on the gun, fill it half way with whatever cleaner is required for your coating. Cover and shake it a bit to loosen any residue. Pull the trigger and drain. Fill the atomizing head two more times with cleaner and drain through the tip by pulling the trigger. Pull the atomizing head straight off the gun. Do not twist as you're pulling. Fill the needle port on the back side of the atomizing head with cleaner and drain. Inspect to make sure there is no residue left in the atomizing head and repeat if needed.

Have a question about this product?

Fill the form below and we will respond to you as soon as possible.