Free Shipping on Orders Over $299 (Restrictions Apply)

Conventional Air Spray Technology

Conventional Air Spray Technology Info

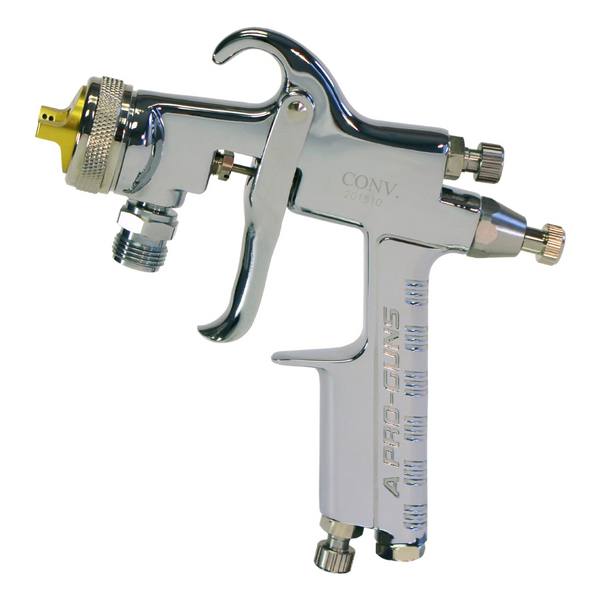

Conventional Air Spray

Conventional air spray (siphon/gravity/pressure feed) is the oldest system, coming into prominence during the 1920's with the growth of the automobile and furniture industries.

Advantages

Conventional air spray lays claim to two basic advantages over the other methods as follows.

Control. This is the most controllable process available. The spray operator, when properly trained, can control the spray pattern from a fine dot to a large production-type spray pattern. This permits the spraying of small or large areas without changing guns or nozzles.

Also the degree of atomization can be controlled. This process provides the finest degree of atomization available in a hand-held system. Needless to say, it is the choice for those who want the best quality finish possible.

Versatility. This process affords the operator the ability to spray the widest range of coating materials. It is also the easiest system to operate and maintain. Just the fact that the process had been around so long has resulted in a huge inventory of equipment, plus volumes of knowledge regarding application techniques.

Disadvantages

On the other hand, conventional air spray has a low level of transfer efficiency. Often, more material is wasted than is actually deposited on the part. This condition is usually aggravated by excessive and poor operator technique. Air spray also consumes large amounts of compressed air (7-35 cfm at 100 psi).

How the System Works

The material to be sprayed is supplied to the spray gun by either a siphon or gravity cup mounted to the gun or by a pressure feed device such as a pressure tank or pump. When the gun is triggered, the material is discharged through the fluid nozzle of the gun in the form of a liquid stream. Upon exiting the gun, this stream is immediately surrounded by a hollow column of compressed air, usually under pressure, emitted from the center of the air nozzle of the gun. The action of this column of air on the fluid stream converts it into small droplets and imparts forward velocity to them. Additional jets of high-pressure compressed air from the face and horns of the air nozzle are directed into the droplets, forming even smaller droplets and an elliptical or fan spray pattern.

The ability to control these forces at work at the head of an air spray gun is the key to a successful spray application. The proof that you have this control is in the quality of the spray pattern produced.