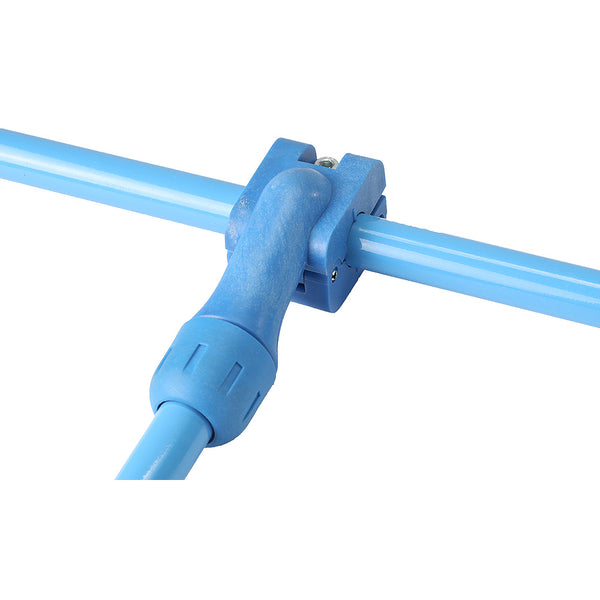

RapidAir FastPipe Saddle Drop Fitting (Pipe x Pipe - Various Sizes)

RapidAir FastPipe Saddle Drop Fitting (Pipe x Pipe - Various Sizes)

$27.85

The RapidAir FastPipe saddle drop fitting is for use with the FastPipe blue rigid aluminum air pipe. The saddle drop fitting allows for future drop legs to be created and installed off the main line in seconds with no cutting or reworking! (Use fastener or pipe clip on either side of the union fitting).

Description

Specifications:

- FastPipe saddle drop sizes (main pipe x drop pipe): 1” x 1”, 1 ½” x ¾”, 1 ½ “ x 1”, 2” x ¾”, 2” x 1”, 3” x ¾”, 3” x 1”

- Saddle drop fittings are sold individually

- Compression style

- Nylon with fiberglass reinforcement ( 1”, 1 ½”, 2”, 3” fittings)

- O-Ring seal material is Nitrile

- Bite ring material is stainless steel

- Maximum operating pressure (190 psi)

- Temperature range (0° F – 140° F)

- Conforms to NFPBUL94HB fire resistant & flammability standards

- Meets OSHA guidelines

Features & Benefits:

- Lightweight, easy install

- FastPipe spanner wrenches required for quick & easy installation

- Secure fit ensures no leaks

- Adaptable to existing types of air piping

- Compatible with common compressor oils

Installation Steps (see pictures above):

- Position saddle drop opposite the side of the pipe that needs the hole. Tighten securely and mark the pipe by the raised locating mark on the fitting. Mark the pipe both horizontally and vertically along the fitting edge.

- Drill thru one side of pipe with the drill bit, using the hole in the fitting as a locator.

- Insert the saddle drop gasket into the molded cavity.

- Position the saddle drop over the drilled hole with aligning marks, tighten securely.

- Attach the necessary drop pipe or threaded adapter.

Saddle Drop Installation Tips:

- System must be depressurized before installing, wear eye protection

- The drop can be used in any position on the pipe

- Avoid putting the hole at the bottom of the pipe to prevent condensate or debris from entering the drop pipe

- To prevent chips from entering the pipe interior, stop drilling occasionally and blow out chips, grease the end of the drilling tool

- Allen wrench for tightening is 6mm size

*(Please note that the Pipe Selection Guide and Quote Form can be found below. Please secure pipe with fasteners every 10ft as well as on either side of any fittings. Please review the fittings, fasteners and outlets available for your FastPipe Selection).

Related Products

Product Inquiry

Have a question about this product?

Fill the form below and we will respond to you as soon as possible.

Specifications:

- FastPipe saddle drop sizes (main pipe x drop pipe): 1” x 1”, 1 ½” x ¾”, 1 ½ “ x 1”, 2” x ¾”, 2” x 1”, 3” x ¾”, 3” x 1”

- Saddle drop fittings are sold individually

- Compression style

- Nylon with fiberglass reinforcement ( 1”, 1 ½”, 2”, 3” fittings)

- O-Ring seal material is Nitrile

- Bite ring material is stainless steel

- Maximum operating pressure (190 psi)

- Temperature range (0° F – 140° F)

- Conforms to NFPBUL94HB fire resistant & flammability standards

- Meets OSHA guidelines

Features & Benefits:

- Lightweight, easy install

- FastPipe spanner wrenches required for quick & easy installation

- Secure fit ensures no leaks

- Adaptable to existing types of air piping

- Compatible with common compressor oils

Installation Steps (see pictures above):

- Position saddle drop opposite the side of the pipe that needs the hole. Tighten securely and mark the pipe by the raised locating mark on the fitting. Mark the pipe both horizontally and vertically along the fitting edge.

- Drill thru one side of pipe with the drill bit, using the hole in the fitting as a locator.

- Insert the saddle drop gasket into the molded cavity.

- Position the saddle drop over the drilled hole with aligning marks, tighten securely.

- Attach the necessary drop pipe or threaded adapter.

Saddle Drop Installation Tips:

- System must be depressurized before installing, wear eye protection

- The drop can be used in any position on the pipe

- Avoid putting the hole at the bottom of the pipe to prevent condensate or debris from entering the drop pipe

- To prevent chips from entering the pipe interior, stop drilling occasionally and blow out chips, grease the end of the drilling tool

- Allen wrench for tightening is 6mm size

*(Please note that the Pipe Selection Guide and Quote Form can be found below. Please secure pipe with fasteners every 10ft as well as on either side of any fittings. Please review the fittings, fasteners and outlets available for your FastPipe Selection).

Have a question about this product?

Fill the form below and we will respond to you as soon as possible.